The take of scrap metal shredder machines in recycling and waste management With regard to recycling and garbage disposal, industrial wastes are recycled into valuable resources through a rapidly-state-of-the-art system using an aluminum profile shredders. Made to demolish anything from an old vehicle and scrap appliances, destroying them into tiny pieces that can be more easily treated or melted are these useful tools agreed for medium-heavy challenges in machine administrations. These are advanced machines as technology continues to evolve, providing an opportunity for businesses to adopt sustainable practices and execute their operation at the highest levels of efficiency.

Understanding New Developments in Scrap Metal Shredder Machines

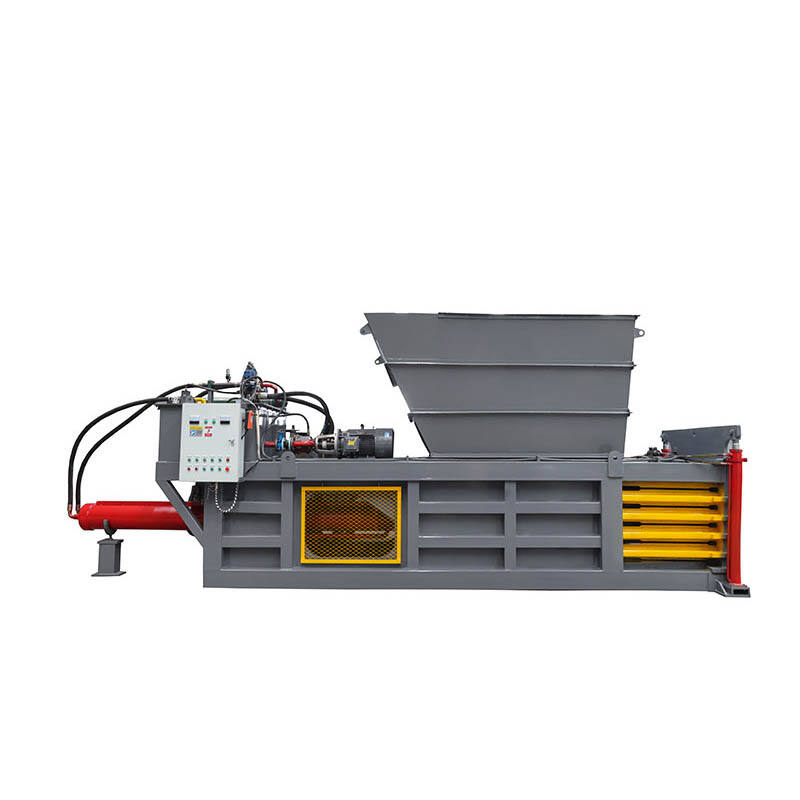

Scrap metal shredder manufacturers have come up with excellent innovations that can handle myriad operational requirements. Current variants are available with cutting edge features like automatic feed control systems, enhanced shredding chambers for better throughput and intelligent monitoring that helps to reduce the machine downtime & maintenance costs Some of these machines also come with noise reduction technologies so they not only satisfy environmental regulations but are more efficient work for workers.

Best Performing Metal Shredders to Optimize Efficiency

Any valuable metal recycling project has efficiency as a top priority. Today's shredders that are high-torque, low-speed use cantilevered shafts at both ends to provide the most benefit for greater throughput and lower energy costs. These machines are built to last with wear-resistant materials, which means less frequent blade replacement. Moreover, innovative systems for magnetic material separation ensure the purity of recycling materials by separating metal particles into ferrous and non-ferrous types in order to provide a kind of clean end product.

How Shredder Machines Are Paving the Way for Sustainable Business Practices

Virtually impossible now, sustainability is not a convenient option for the global business house anymore. This turnkey approach to size reduction uses an industrial shredder by a typical scrap metal recycler that can shred and separate the various materials in one step helping cash flow while reducing volumes, manpower and cleaner recycling operations for certain material streams. This level of machinery could potentially process a wider variety and quantity of materials, even difficult to recycle items (eg e-waste), supporting zero waste goals. They even include energy recovery systems which convert the heat produced during shredding into reusable power, resulting in a reduction to the carbon footprint of recycling operations.

A Complete Guide of Finding the Perfect Scrap Metal Shredder for Your Needs

Selecting the right scrap metal shredder requires a deep respect for many factors. First, you need to determine how much scrap are you gonna process and what type of metal do they have periodically. It is also possible that the evaluation will help you to pinpoint down machines with right capacities and shredding abilities -This final point does not relate to rest of these two points discussed here. Next, reflect upon space constraints and power availability at your location. If you have not much space then the portable or compact shredders would work well. Finally, consider the machine's maintenance requirements and level of after-sales support provided by the manufacturer. Go for major manufacturers recognized by the credibility and completeness of service Provided.

Find Out About the Best Range Of High-performance Shredders Present In The Market Today,

Fast forwarding to the present market, there are a lot of high-throughput shredders available for all budgets and operational scales. There is a shredder size and style to suit the needs of almost every business, from industrial-scale models capable of processing several tons per hour right through to compact machines designed for small scale operations. Flexible Power, rotor design options with FEAs to fit specific client needs by most of the manufacturers.

Therefore, the scrap metal shredder machines have changed face to meet this growing need for rapid and sustainable recycling methods. If companies choose the right shredder, not only do they make their daily work easier but also contribute to a clean environment. Keep in mind, a smart decision here can be very profitable and better for the plant into which we all call home.

Table of Contents

- Understanding New Developments in Scrap Metal Shredder Machines

- Best Performing Metal Shredders to Optimize Efficiency

- How Shredder Machines Are Paving the Way for Sustainable Business Practices

- A Complete Guide of Finding the Perfect Scrap Metal Shredder for Your Needs

- Find Out About the Best Range Of High-performance Shredders Present In The Market Today,

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ