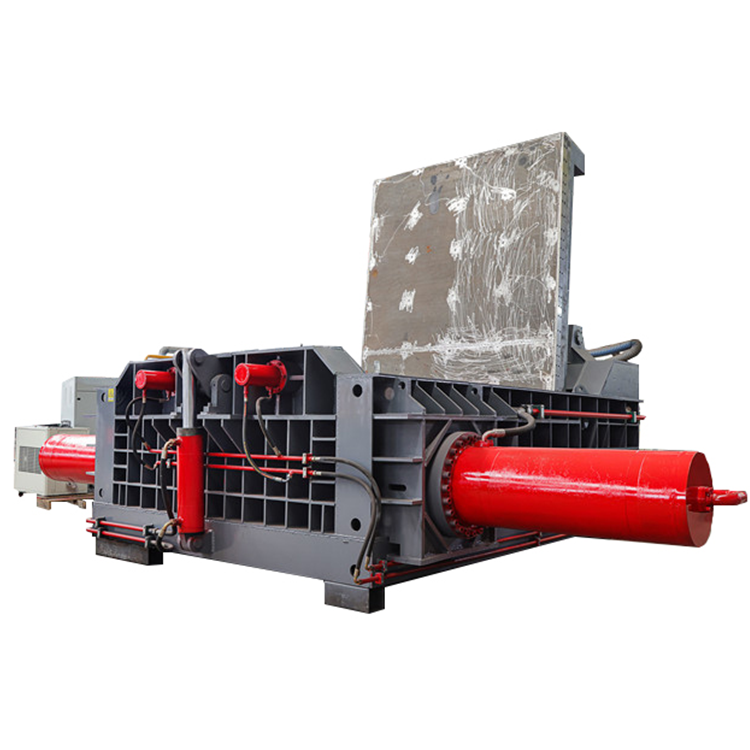

Full Automatic Hydraulic Scrap Metal Sheet Baler Machine for Aluminum Can Copper Wire Iron Drum Steel Press Baler

In today's industrial landscape, managing scrap metal efficiently is crucial for both economic and environmental reasons. Scrap metal balers are vital machines that help businesses streamline their waste management processes by compressing loose metal scrap into dense, manageable bales. These balers not only optimize space and reduce handling costs but also play a significant role in promoting recycling and sustainability.

What Are Scrap Metal Balers?

Scrap metal balers are heavy-duty machines designed to compress various types of metal scrap into compact bales. These bales are easier to transport and store, making them an essential tool in industries that produce large amounts of metal waste, such as manufacturing, automotive, and demolition sectors. Balers can handle different types of metals, including aluminum, steel, copper, and iron, and are available in various sizes to suit different operational needs.

Key Benefits of Scrap Metal Balers

1. Space Optimization

One of the primary benefits of using scrap metal balers is the significant reduction in waste volume. By compressing loose metal into dense bales, these machines free up valuable space in warehouses, factories, and recycling facilities. This space optimization allows businesses to store more material in a smaller area, improving overall operational efficiency.

2. Cost Savings

Reducing the volume of scrap metal not only saves space but also lowers transportation and disposal costs. Compressed bales are easier and more cost-effective to transport, as they require fewer trips and less storage space. Additionally, many recycling companies pay higher prices for baled scrap metal due to its ease of handling and higher quality, creating an additional revenue stream for businesses.

3. Enhanced Recycling Efforts

Scrap metal balers play a critical role in promoting recycling. By converting loose metal scrap into bales, these machines make it easier for recycling centers to process the material, reducing the need for new raw materials and minimizing environmental impact. This contributes to the circular economy, where materials are reused and recycled, reducing waste and conserving resources.

4. Improved Workplace Safety

Loose metal scrap can create hazardous working conditions, leading to potential injuries and accidents. Scrap metal balers help maintain a safer work environment by keeping scrap metal organized and contained. This reduces the risk of accidents, such as cuts, punctures, and trips, improving overall workplace safety.

Applications of Scrap Metal Balers

1. Manufacturing Industry

Manufacturing plants often generate significant amounts of metal waste during production. Scrap metal balers help these facilities manage their waste more efficiently, reducing storage needs and facilitating recycling. By baling scrap metal, manufacturers can also improve their environmental footprint and align with sustainability goals.

2. Automotive Industry

The automotive industry produces vast quantities of metal scrap, from car manufacturing to repair and dismantling. Scrap metal balers enable automotive businesses to handle this waste more effectively, lowering disposal costs and promoting recycling. Baled metal is easier to transport to recycling facilities, where it can be processed into new materials.

3. Demolition and Construction

In demolition and construction projects, large amounts of metal waste are often generated. Scrap metal balers allow these industries to manage waste on-site, compressing materials for easier transport and disposal. This not only improves efficiency but also supports the recycling of valuable metals.

4. Recycling Centers

Recycling centers rely heavily on scrap metal balers to process and prepare metal waste for further recycling. These machines enhance the efficiency of recycling operations by converting loose scrap into high-quality bales that are easier to sort, handle, and recycle.

Conclusion

Scrap metal balers are essential tools for businesses seeking to optimize their waste management processes. By reducing the volume of scrap metal, lowering costs, and promoting recycling, these machines help industries improve their operational efficiency and contribute to environmental sustainability. As the demand for sustainable practices continues to grow, the role of scrap metal balers in waste management will become increasingly important, making them a valuable asset in the pursuit of a greener future.

Recommended Products

Hot News

-

Diverse Applications of Waste Paper Balers in Various Industries

2024-07-23

-

Hot Sale PVC Pulverizer Paper Wood Pallet Plastic Crusher Machine Double Shaft Shredder

2024-06-21

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2024-06-18

-

Plastic lump textile metal shredder machine

2024-06-15

-

Introducing the Mighty Metal Shredder Machine

2024-05-25

-

Two-shaft Shredder: A Powerful Tool for Solid Waste Treatment

2024-10-15

-

Tire Shredder for Tire Recycling | Tire Shredding Systems

2024-06-04

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2023-10-10

-

Embrace Sustainability: The Power Of Tire Recycling

2023-10-10

-

Industrial Shredding Machinery: A Growing and Diversifying Market

2023-10-10

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ