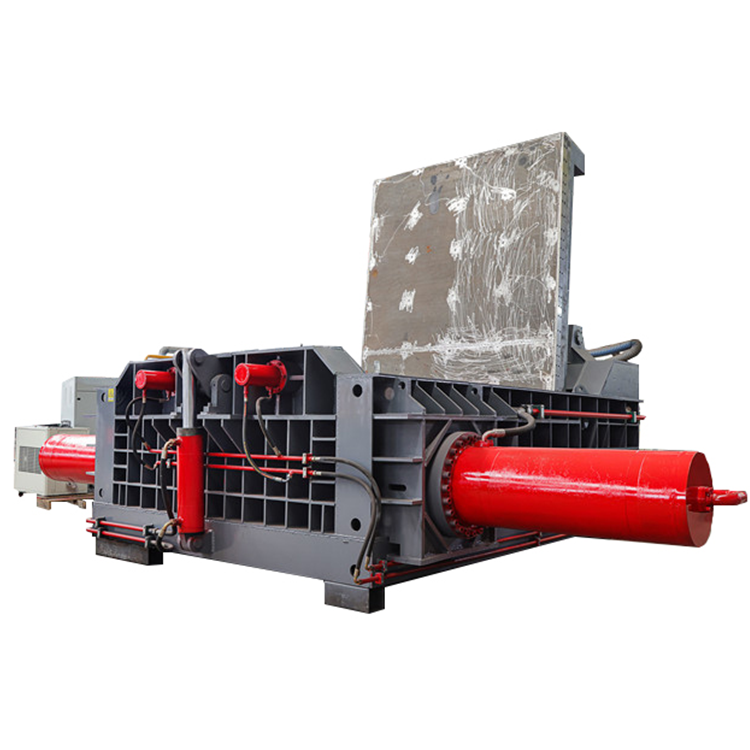

Series automatic metal squeeze waste metal hydraulic scrap metal baler

Hydraulic metal balers press the leftover of all kinds of metal meterial (steel shavings, scrap steel) to be qualified furnace in the shape of cuboids, octagon, cylinder and so on, which not only decreases the freight and smelting costs, but also increase the speed of casting. This machine is mainly applicable to steel mills, recycling industries and ferrous metallurgical works.

- Parameters

- Features

- Application

- Service

- Video

- Inquiry

- Related Products

Parameters

| Model | Nominal thrust (kn) | Dimension of compress room (mm) | Bale dimension (mm) | Bale weight (kg) | Capacity (t/h) | Power (kw) |

| 63 | 630 | 1000*600*500 | 190*190 | 15-30 | 0.4-0.8 | 7.5 |

| 100 | 1000 | 1000*700*550 | 230*230 | 30-40 | 0.6-1.2 | 11 |

| 125 | 1250 | 1200*700*600 | 300*300 | 50-75 | 1.2-1.5 | 15 |

| 135 | 1350 | 1400*600*600 | 600*240 | 60-80 | 1.5-2.8 | 22 |

| 160 | 1600 | 1600*1000*800 | 400*400 | 110-150 | 2.2-3.0 | 22 |

| 200 | 2000 | 1800*1400*900 | 450*450 | 210-300 | 3.0-5.0 | 22*2 |

| 250 | 2500 | 2000*1750*1200 | 500*500 | 250-280 | 5.0-6.3 | 22*2 |

| 315 | 3150 | 2500*2000*1200 | 500*500 | 250-360 | 4.0-6.5 | 37*2 |

| 400 | 4000 | 3000*2000*1200 | 500*600 | 250-380 | 6.8-8.0 | 45*2 |

Features

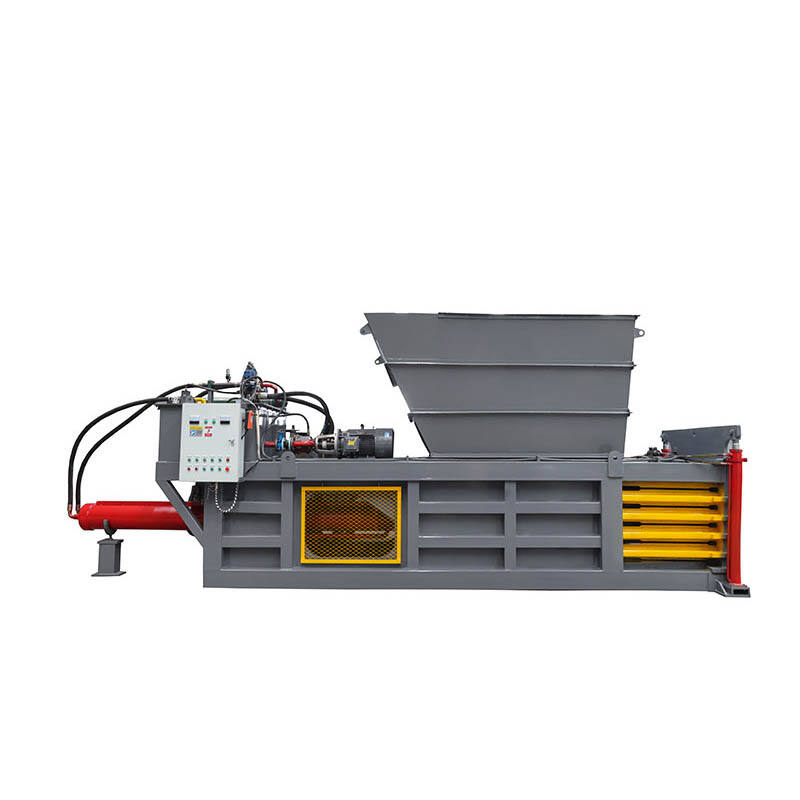

1. The discharging types fall into turning over, push out, forward out and manual lifting.

2. It is unnecessary to fix foot screw and a diesel engine can be used in case of power supply unavailability.

3. No fang bolts needed for installation; diesel engine can be used as power when electric power is unavailable.

4. The extrusion force ranges from 63t to 400t, totaling 10 grades for customers' selection, and productivity being from 3.2t/shift to 64t/shift.

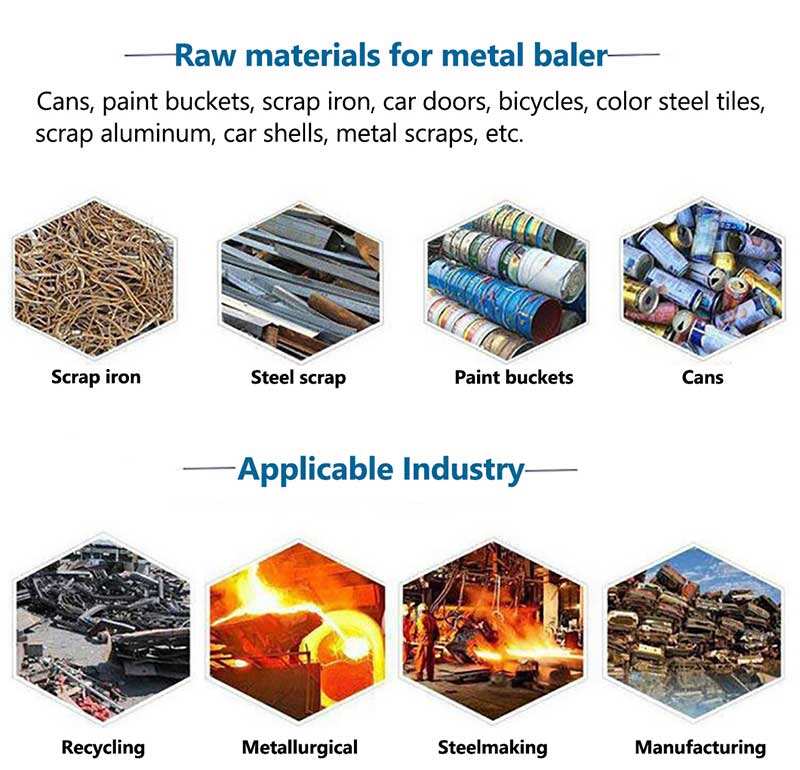

Application

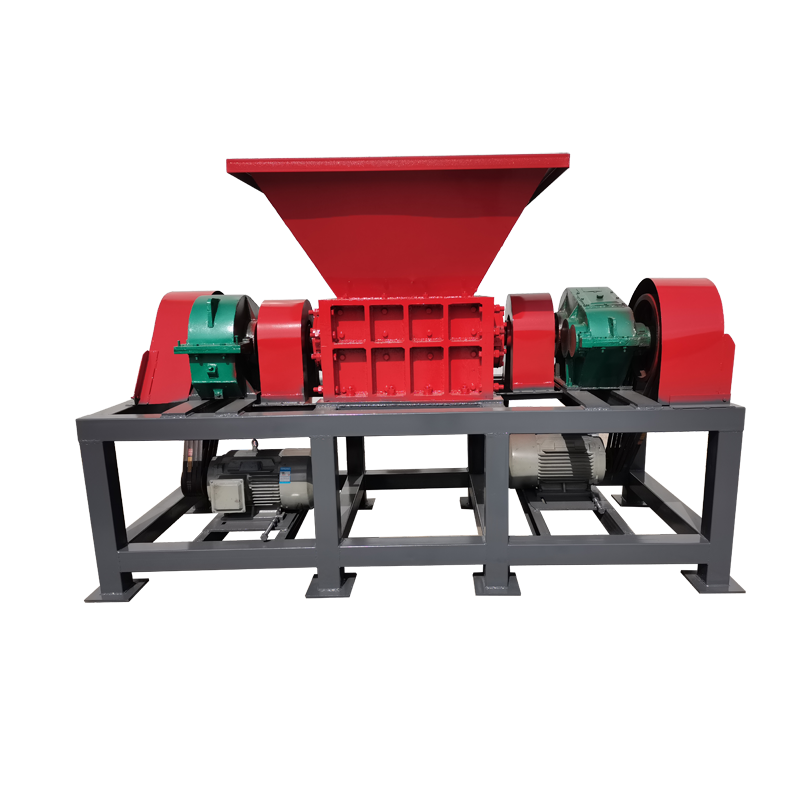

Scrap metal baler is suitable for the aluminum alloy factory, steel casting factory, aluminum casting factory, copper casting factory, etc. to compress and pack the aluminum chip, steel chip, iron chip and copper chips for melting down, It can replace the waste steel, pig iron, aluminum ingot and waste copper as row materials and reduce the fire loss. This scrap metal baler can press coldly the cast iron chip, steel chip, copper chip and aluminum chip into 3-6Kg cylinder caky blocks, easy for transportation, furnace casting, during the whole course of which, the temperature adding and the additive or other craftwork are not needed.

Service

Pre-Sales:

Act as a good adviser and assistant of clients,enable them to get rich and competitive from the returns of their investment.

1. Select suitable equipment model.

2. Design and manufacture products according to clients special requirements.

3. Train technical personnel for clients.

4. Professional suggestion for customer.

Service During The Sales:

Respect clients, devote ourselves to improving the total value of clients.

1. Take photos ( including raw material, semi-products, final products and loading products ) .

2. Pre-check and accept products ahead of delivery.

3. Prepare all clearance documents, so that the customer clearance smoothly.

After-sales service:

Provide considerate service to minimize clients worries.

1. Provide civil engineering drawings of the equipment.

2. Free training ( including installation, maintaince ) to every customer.

3. Install and debug the equipment, ensure the dryer running smoothly.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ