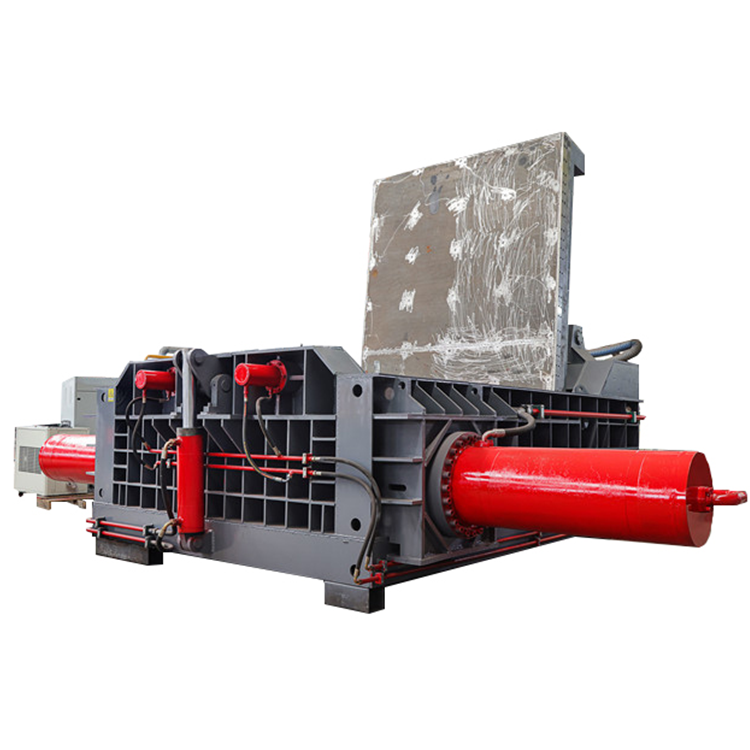

Hydraulic Metal Baler Baling Press Machine Steel Iron Aluminum Copper Baler

In industries where metal is a primary material, waste management becomes a critical concern. Managing scrap metal efficiently is not only essential for maintaining a clean and safe working environment but also for maximizing profitability and sustainability. The Hydraulic Metal Baler offers a robust solution to these challenges, providing a powerful and versatile tool for compressing a wide range of metal materials into compact, transportable bales.

What is a Hydraulic Metal Baler?

A hydraulic metal baler is an industrial machine specifically designed to compress and bind scrap metal, such as steel, iron, aluminum, and copper, into dense, manageable bales. These bales are easier to store, transport, and recycle, making the baler an invaluable asset for industries like manufacturing, automotive, recycling, and construction.

Key Features of the Hydraulic Metal Baler

1. Powerful Hydraulic System

The core of the metal baler is its hydraulic system, which delivers immense force to compress metal waste into compact bales. This system is designed to handle various metals with different densities, ensuring consistent and reliable performance across a wide range of materials.

2. Versatility

One of the standout features of this baler is its ability to process multiple types of metals. Whether it’s heavy steel beams, lightweight aluminum sheets, or copper wiring, the machine efficiently compacts them all. This versatility makes it a practical choice for businesses dealing with diverse metal waste.

3. Robust Construction

Built for heavy-duty industrial use, the hydraulic metal baler features a durable design that ensures long-lasting performance. The machine is constructed from high-grade steel and other materials designed to withstand the rigors of continuous operation, even in the most demanding environments.

4. Automation and Ease of Use

Modern hydraulic balers are equipped with advanced automation features that make the baling process more efficient and less labor-intensive. Operators can control the machine through an intuitive interface, allowing for quick adjustments and easy monitoring of the baling process.

5. Space and Cost Efficiency

By reducing the volume of metal waste by up to 90%, the baler significantly decreases the space required for storage and the costs associated with transportation. This compression also simplifies handling and processing, making the overall waste management process more streamlined and cost-effective.

Benefits of Using a Hydraulic Metal Baler

1. Enhanced Operational Efficiency

With the ability to compress large volumes of scrap metal into smaller, uniform bales, the hydraulic baler improves operational efficiency. This not only speeds up the process of waste management but also reduces the time and labor required for handling and transportation.

2. Environmental Sustainability

Recycling is a key component of sustainable practices, and the hydraulic metal baler plays a crucial role in this process. By making it easier to store and transport scrap metal, the baler encourages recycling, reducing the need for new raw materials and lowering the environmental impact of metal production.

3. Improved Safety

Loose scrap metal can pose significant safety hazards, including sharp edges and unstable piles that can lead to accidents. The baler helps mitigate these risks by compressing metal waste into secure, stable bales, creating a safer workplace environment.

4. Cost Savings

In addition to reducing transportation and storage costs, the baler can also contribute to revenue generation. Recycled metals are often in high demand, and businesses can sell their compressed bales to recycling facilities, creating an additional income stream.

Applications of the Hydraulic Metal Baler

1. Manufacturing

In manufacturing settings, metal offcuts, shavings, and defective products are common byproducts. The hydraulic metal baler efficiently processes these materials, turning waste into valuable bales that can be recycled or sold.

2. Automotive Industry

The automotive industry generates significant amounts of metal waste, from old car parts to manufacturing scraps. The baler helps manage this waste effectively, compressing it for easy transport to recycling facilities.

3. Recycling Centers

Recycling centers rely on efficient processing of materials to maximize profitability. The hydraulic metal baler is an essential tool in these facilities, allowing for the efficient handling and baling of various metals, ready for recycling.

4. Construction and Demolition

Construction and demolition projects often produce large amounts of metal waste. The hydraulic metal baler simplifies the management of this waste, compressing metal scraps on-site for easier disposal or recycling.

Conclusion

The Hydraulic Metal Baler is a powerful, versatile, and essential tool for any industry that deals with metal waste. Its ability to compress and bind various metals into compact bales not only optimizes space and reduces costs but also supports sustainable practices by making recycling easier and more efficient. Whether you’re in manufacturing, recycling, construction, or any other industry that generates metal waste, investing in a hydraulic metal baler is a smart move that offers both immediate and long-term benefits.

Recommended Products

Hot News

-

Diverse Applications of Waste Paper Balers in Various Industries

2024-07-23

-

Hot Sale PVC Pulverizer Paper Wood Pallet Plastic Crusher Machine Double Shaft Shredder

2024-06-21

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2024-06-18

-

Plastic lump textile metal shredder machine

2024-06-15

-

Introducing the Mighty Metal Shredder Machine

2024-05-25

-

Two-shaft Shredder: A Powerful Tool for Solid Waste Treatment

2024-10-15

-

Tire Shredder for Tire Recycling | Tire Shredding Systems

2024-06-04

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2023-10-10

-

Embrace Sustainability: The Power Of Tire Recycling

2023-10-10

-

Industrial Shredding Machinery: A Growing and Diversifying Market

2023-10-10

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ