Streamlining Metal Recycling: The Role of Scrap Metal Balers

As the world increasingly prioritizes sustainability and environmental responsibility, the recycling industry has become more vital than ever. One essential piece of equipment in this sector is the scrap metal baler. This powerful machine plays a crucial role in compressing and managing scrap metal, making it easier to transport, store, and recycle. In this article, we'll delve into what a scrap metal baler is, how it works, its benefits, and its applications in various industries.

What is a Scrap Metal Baler?

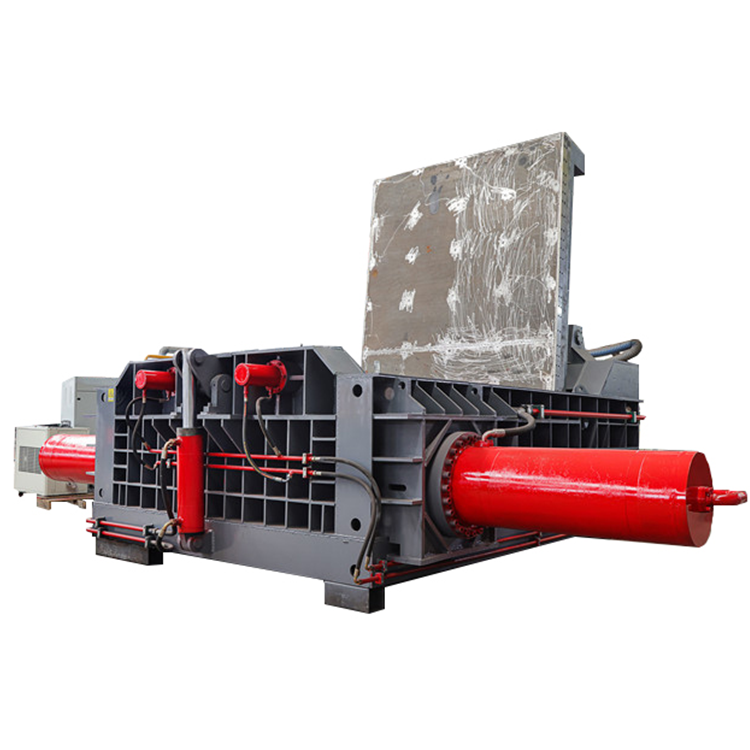

A scrap metal baler is an industrial machine designed to compress metal scrap into dense bales for easier handling and transportation. These bales can include various types of metals, such as steel, aluminum, copper, and iron. By compacting these materials, scrap metal balers enhance the efficiency of recycling processes and help reduce waste volume significantly.

How Does a Scrap Metal Baler Work?

The operation of a scrap metal baler typically involves the following steps:

-

Feeding: Scrap metal is loaded into the baler, either manually or via an automated conveyor system. This can include everything from small metal pieces to larger components.

-

Compression: The baler uses hydraulic force to compress the metal scrap into a compact bale. The machine applies significant pressure, which reduces the volume of the scrap, making it easier to manage.

-

Binding: Once the bale reaches the desired size and density, it is tied off using wire or plastic straps to keep it intact during handling and transportation.

-

Ejection: The finished bale is ejected from the baler, ready for storage or shipping to recycling facilities.

This efficient process allows for continuous operation, enabling businesses to manage large volumes of metal scrap effectively.

Key Features of Scrap Metal Balers

1. High Compression Capability

One of the most significant advantages of scrap metal balers is their ability to compress materials into very dense bales. This feature not only maximizes storage space but also makes transportation more efficient.

2. Durable Construction

Scrap metal balers are built to withstand the rigors of heavy-duty operations. Constructed from high-quality materials, these machines can handle the toughest metals without compromising performance.

3. Versatility

Scrap metal balers can process various types of metals, making them versatile tools for recycling operations. Whether dealing with steel, aluminum, or copper, these machines can handle a wide range of materials, allowing for more efficient recycling.

4. Automated Features

Many modern scrap metal balers come equipped with automated features, reducing the need for manual labor. This includes automatic feeding, binding, and ejection systems, which streamline the entire baling process.

Benefits of Using a Scrap Metal Baler

1. Cost Savings

By compacting scrap metal into bales, companies can reduce waste disposal costs. Baled metal takes up significantly less space, allowing for more efficient storage and fewer trips to recycling facilities.

2. Enhanced Recycling Efficiency

Baled scrap metal is easier to handle and process at recycling centers. Many facilities prefer receiving metal in bale form, as it simplifies sorting and processing, leading to quicker turnaround times.

3. Increased Scrap Value

Baled scrap metal often fetches a higher price compared to loose scrap. Recycling companies are more likely to offer competitive rates for baled materials, maximizing the financial return for businesses.

4. Environmental Responsibility

By efficiently recycling scrap metal, businesses contribute to reducing landfill waste and conserving natural resources. Using a scrap metal baler helps promote sustainable practices and supports a circular economy.

5. Improved Safety

Managing loose scrap metal can pose safety hazards, including sharp edges and unstable piles. Baling metal improves workplace safety by reducing clutter and creating compact, manageable bales that are easier to handle.

Applications of Scrap Metal Balers

1. Recycling Centers

Recycling facilities are the primary users of scrap metal balers. These centers rely on balers to process large volumes of metal waste efficiently, ensuring that materials are prepared for recycling.

2. Manufacturing Plants

Manufacturing operations often generate significant amounts of metal waste during production. Scrap metal balers help these plants manage their scrap efficiently, turning waste into compact bales that can be sold or recycled.

3. Scrapyards

Scrapyards collect various types of metal waste, including vehicles and appliances. Scrap metal balers help these facilities organize and compress their scrap, making it easier to sell to recycling companies or transport for processing.

4. Automotive Industry

In the automotive sector, scrap metal balers are invaluable for managing waste generated during vehicle dismantling and repair. Baling metal scrap from old vehicles simplifies the recycling process and helps recover valuable materials.

Conclusion

The scrap metal baler is an essential tool for any business involved in recycling operations. By compacting scrap metal into manageable bales, these machines improve efficiency, reduce costs, and enhance environmental responsibility. As industries continue to prioritize sustainable practices, investing in a scrap metal baler is not just a smart business decision but also a commitment to a greener future. With their ability to process various metals and optimize recycling efforts, scrap metal balers are truly vital in modern waste management and recycling strategies.

Recommended Products

Hot News

-

Diverse Applications of Waste Paper Balers in Various Industries

2024-07-23

-

Hot Sale PVC Pulverizer Paper Wood Pallet Plastic Crusher Machine Double Shaft Shredder

2024-06-21

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2024-06-18

-

Plastic lump textile metal shredder machine

2024-06-15

-

Introducing the Mighty Metal Shredder Machine

2024-05-25

-

Tire Shredder for Tire Recycling | Tire Shredding Systems

2024-06-04

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2023-10-10

-

Embrace Sustainability: The Power Of Tire Recycling

2023-10-10

-

Industrial Shredding Machinery: A Growing and Diversifying Market

2023-10-10

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ