Unlocking the Potential: Applications of Scrap Metal Balers

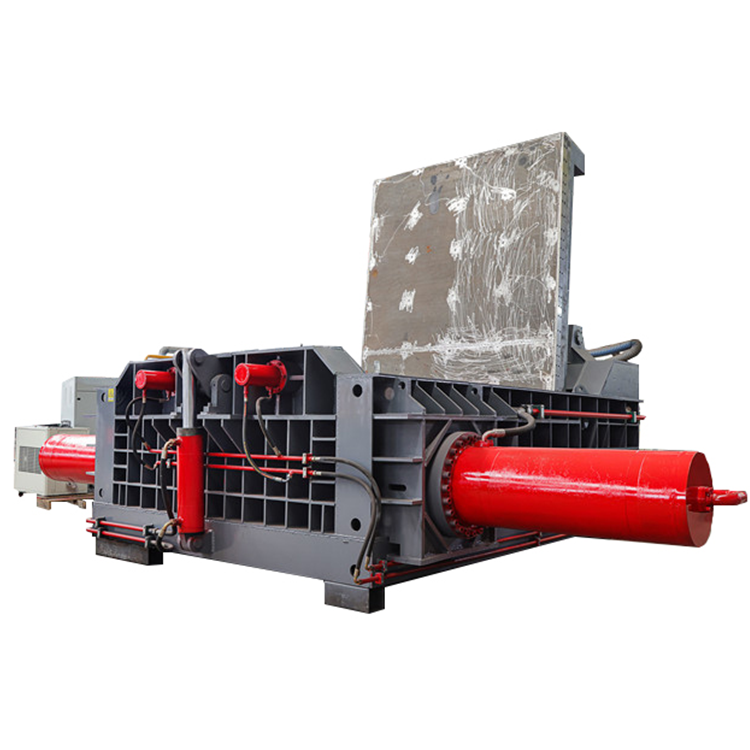

Scrap metal balers are vital machines in modern industries, offering an efficient solution for compressing and managing metal waste. These robust machines convert loose scrap metal into dense, manageable bales, making storage, transportation, and recycling more practical. Here's a look at how different sectors are leveraging scrap metal balers to enhance their operations and promote sustainability.

## Recycling Centers: Streamlining Operations

### How They Benefit:

- **Volume Reduction**: Scrap metal balers compress large quantities of metal waste, significantly reducing volume. This makes storage more efficient and transport more cost-effective.

- **Operational Efficiency**: Compressed bales are easier to handle and process, speeding up recycling operations.

- **Improved Quality**: Baling ensures that scrap metal is compact and uncontaminated, resulting in higher quality recycled material.

### Example:

A local recycling center might receive tons of mixed metal scrap daily. By using a scrap metal baler, they can reduce the bulk of this waste, making it easier to ship to specialized recycling facilities.

## Manufacturing and Industrial Facilities: Optimizing Waste Management

### How They Benefit:

- **Space Optimization**: In manufacturing, space is a premium. Balers compact metal waste, freeing up valuable floor space for production activities.

- **Cost Savings**: By reducing the volume of waste, transportation costs decrease, and companies can also generate revenue by selling baled scrap to recyclers.

- **Environmental Compliance**: Effective waste management helps industries comply with environmental regulations, reducing potential fines and enhancing corporate responsibility.

### Example:

A car parts manufacturer generates metal offcuts and shavings. A baler compresses this scrap into dense bales, reducing storage needs and creating a new revenue stream from recycled materials.

## Automotive Industry: Managing Scrap Efficiently

### How They Benefit:

- **Efficient Handling**: From manufacturing to repair shops, the automotive industry deals with large amounts of metal waste. Balers simplify the handling and disposal of this scrap.

- **Cost Efficiency**: By compacting scrap metal, the industry saves on waste management costs and can sell the bales for recycling, offsetting operational expenses.

- **Sustainability**: Recycling metal waste reduces the need for new raw materials, supporting environmental sustainability.

### Example:

An auto repair shop regularly replaces parts, generating metal waste. Using a baler, they can efficiently compress and store this scrap until it's sold to a recycler, keeping their workspace clean and organized.

## Demolition and Construction: Enhancing Site Safety

### How They Benefit:

- **Safety and Organization**: Construction sites can be hazardous with loose scrap metal. Balers help in compacting and organizing this waste, improving site safety.

- **Cost Reduction**: Reducing the volume of metal waste lowers the cost of disposal and transportation.

- **Resource Recovery**: Recovered metal from demolition projects can be baled and sold, promoting recycling and resource efficiency.

### Example:

A demolition project generates tons of structural steel waste. A scrap metal baler compresses this material, making it easier to transport and sell to recycling firms, turning waste into profit.

## Metal Fabrication Shops: Streamlining Production

### How They Benefit:

- **Space Efficiency**: Fabrication shops generate offcuts and scrap that can clutter the workspace. Balers reduce the volume of this waste, optimizing the available space.

- **Cost Effectiveness**: Compressing scrap metal lowers transportation and disposal costs, and baled scrap can be sold to recyclers.

- **Operational Efficiency**: A clean, organized workspace boosts productivity and safety.

### Example:

A metal fabrication shop produces various custom metal parts, generating scrap. By using a baler, the shop can manage this waste more effectively, maintaining a tidy workspace and creating an additional revenue stream.

## Conclusion

Scrap metal balers are versatile machines that offer numerous benefits across various industries. They enhance operational efficiency, reduce costs, improve safety, and promote environmental sustainability. As industries continue to focus on waste management and recycling, the role of scrap metal balers becomes increasingly vital. By integrating these machines into their operations, businesses can turn metal waste into a valuable resource, supporting both economic and environmental goals.

Recommended Products

Hot News

-

Diverse Applications of Waste Paper Balers in Various Industries

2024-07-23

-

Hot Sale PVC Pulverizer Paper Wood Pallet Plastic Crusher Machine Double Shaft Shredder

2024-06-21

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2024-06-18

-

Plastic lump textile metal shredder machine

2024-06-15

-

Introducing the Mighty Metal Shredder Machine

2024-05-25

-

The Versatility and Importance of Shredders

2024-10-26

-

Two-shaft Shredder: A Powerful Tool for Solid Waste Treatment

2024-10-15

-

Tire Shredder for Tire Recycling | Tire Shredding Systems

2024-06-04

-

Scrap Metal Shredder Machine: A Powerful Tool For Processing Metal Waste

2023-10-10

-

Embrace Sustainability: The Power Of Tire Recycling

2023-10-10

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ